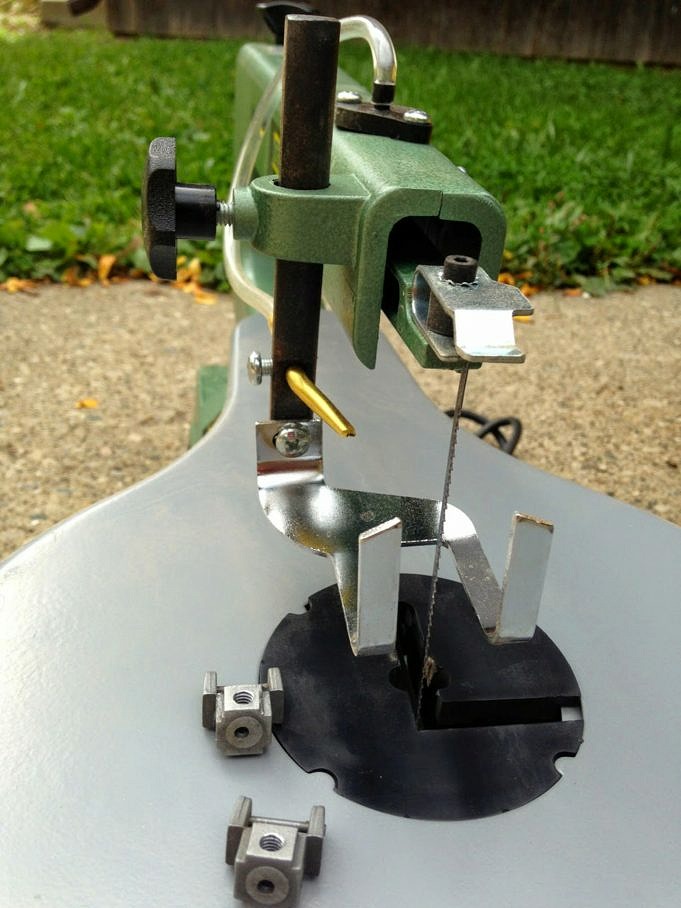

Scroll saw tables can be difficult to put together. This is how to flatten your harbor freight scrollsaw table and make it ready for woodworking.

Important Steps to Remember

Aligning Table

Aligning the table is the first step. You can do this with a straight edge or a level. The straight edge should be placed across the table. Next, adjust the leveling screws so that the table is flat. You should check the top and bottom of the table as well as the sides.

Attaching to the Fence

You use the fence to guide your cuts. The fence should be straight and parallel to your table. It is important that it is properly attached. This can be done by clamping the fence to the table and then screwing it down. The screws should be short enough to not interfere with the blade.

Adjusting Blade

Once the table has been aligned and the fence in place, it is time to adjust its blade. You can do this by loosening the screws at the table’s side. The blade can easily cause injury if you are not careful. Keep your fingers and hands away from the blade. You can adjust the height by moving the screws up or down. The blade can be turned on its side to adjust the angle. After you have adjusted the blade, make sure to tighten them again.

Benefits

Flattening a harbor freight scrollsaw table has many benefits. This can improve the accuracy of the saw and prevent blade binding. It can make it easier to use the saw and increase the quality of the cut.

How do you make a Harbor Freight Scrollsaw Table Flat?

A harbor freight scroll saw table can be made flat using a variety of methods. An angle finder is the most popular method to adjust the angle of a harbor freight scroll saw table. You can also use shims for leveling the table.

Angle Locator:

An angle finder is the best way to flatten a harbor freight scroll saw tablet. You can use this tool to determine the angle of your table and adjust it accordingly. First measure the height at each corner of the table to use the angle finder. The angle finder will match the measurements of the table to determine the angle. To adjust the angle of your table, you can use a wrench or a screwdriver.

Shims:

An angle finder may not be available so shims can be used to flatten a harbor freight scroll saw. Shims can be used to level surfaces and are made of thin pieces either metal or plastic. These can be bought at most hardware shops or online. Measure the height of each corner. Next, measure the height of the table at each corner using a ruler. Place shims underneath the legs of the table until it is level. You can use either of the methods above to flatten a harbor freight scrollsaw table. These methods might not work with all saws. These methods won’t work if the angle or height cannot be adjusted.

If the saw has tilting blades, it is crucial that the table aligns with the blade before you make any adjustments. Flattening a harbor freight scrollsaw table can improve your accuracy and quality. This can prevent blade binding and make it easier to use the saw.

Safety Tips

It is crucial to follow safety precautions when using any power tool. Wearing goggles for protection and a dust mask to prevent you from inhaling the sawdust when operating a scroll saw are two of the safety precautions. It is also important that the table where the scroll saw is mounted be flat. Uneven or warped tables can cause the blade’s to become stuck and kick back, possibly causing injury. The distance between two points on the table’s surface can be used to check its flatness. If the distance between these points is greater than 0.003 inches, then your table is not flat.

Shims can be used to level out uneven tables. To level out a table, shims are thin pieces made of material that can be placed under the legs. Shims can be purchased at most hardware stores or made from cardboard and other thin materials. A leveling compound can also be used to fix an uneven table. A leveling compound is a liquid substance which can be poured on top of the table to help create a flat surface. There are many types of leveling compounds, so make sure you read the instructions before using any.

It is essential to maintain a flat table. You can do this by checking the table for bumps and irregularities, then adjust them as needed. Make sure that the table doesn’t move by tightening the screws holding it in place.

Conclusion